Assembly Automation

SCREW FEEDING

Automation components for screw feeding and screw feed units for fully automatic operation or hand-held use. The SA-1M, SA-1.5, and SA-2.5 feed units may be used with assembly automation’s multi-head drivers or handpieces.

Features:

The vibratory bowls are coated with polymer for longer life and fastener protection. Feed units may be used as handheld or fully automatic systems.

Feed units also include steel sound deadening enclosures and lapped spool high-performance valves. All escapements and tracks are hardened ground tool steel for higher durability.

Hardened inserts are placed in high wearing areas of the bowl. Controls are packaged as a plugin for easier maintenance. Need a Quote? Contact Us

AUTOMATIC SCREWDRIVERS

- Hand-Held Units

- Self Feed Units

- Air or Electric Tools

- Positive Screw Extension

- Torque Reaction Arms

- Single / Multi Spindle Components

- Power Assist Handpieces

Self-Advancing Screwdriver (S.A.S) with an optional torque arm. The S.A.S can be hung from a tool balancer or used with Air Center’s optional torque arm which is adaptable to many types of electric or pneumatic assembly tools. Our self-advancing screwdriver includes a trigger start, powered bit extension, and optional swivel handpiece.

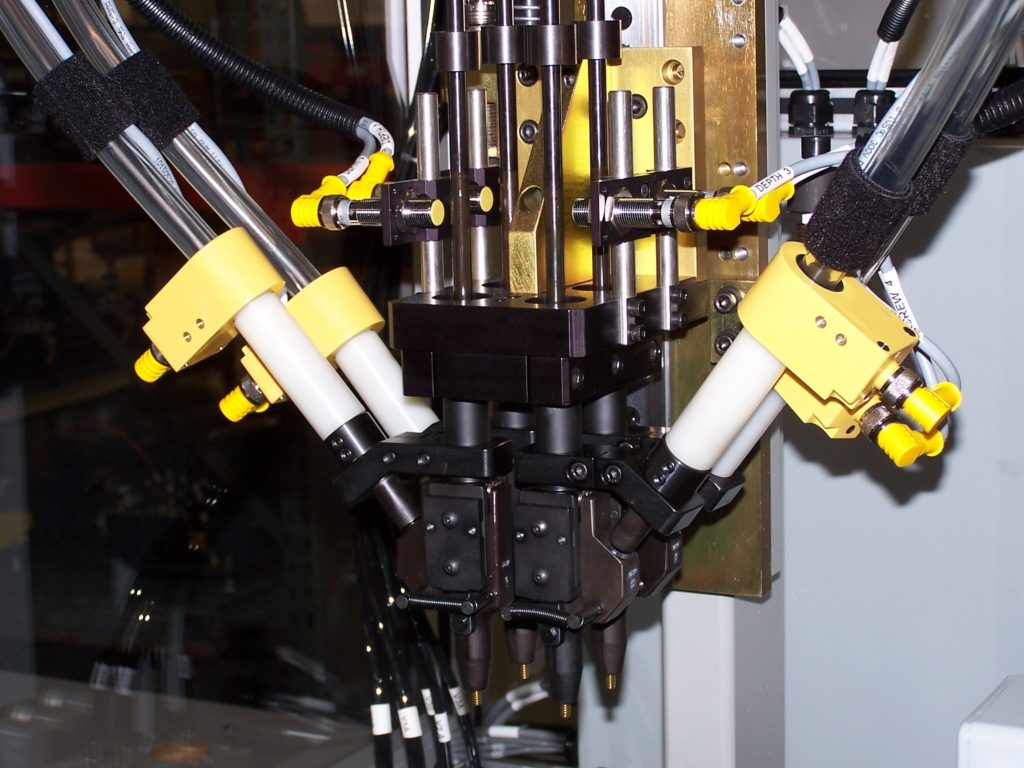

AUTOMATIC SCREWDRIVING SYSTEMS

Multiple sensing options

- Screw Presence

- Depth

- Torque

Use with electric or pneumatic, easy torque adjustment and bit change, and head tooling may be locked in any radial position.

- Head/bit stroke included

- Multiple head styles for difficult access applications

- Bit stroke available for use on robots or subslides

- Offset tooling available for close center applications

- Verticle and Horizontal Operation

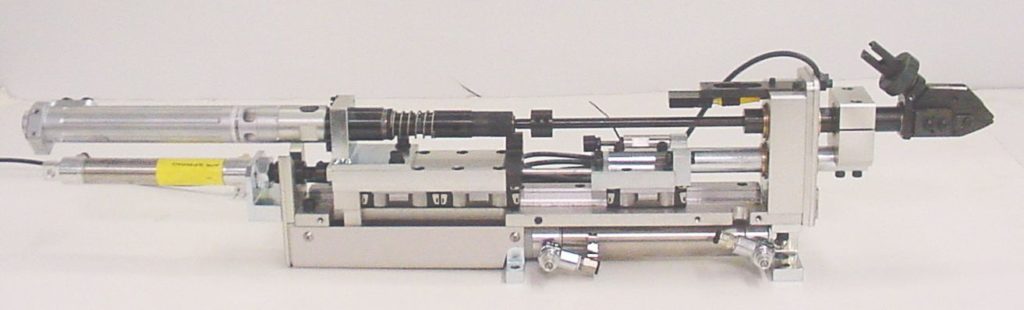

SS-4 SELF-FEED SCREWDRIVER

Lightweight, compact, screwdrivers for robotic assembly applications.

- 20 Nm torque capacity

- 100 mm stroke

- Weight: 6 kg including the tool

- 60 cm overall tool length

- operates in any position, including inverted positions

- Mounting brackets available for most D.C. and pneumatic tools, including Techmotive, Cooper, Stanley, Ingersoll Rand, and Atlas Copco

- Removable cover for a quick bit and tooling changes

- Compression spindle available for light torque delicate joints

- Built-in rear limit and screw depth check sensors

TORQUE REACTION ARM WITH POWER ASSIST

TRT-1

Features include:

Air Center provides controlled screw thrust, positive screw extension, and torque arm joints are all ball-bearing construction with zero backlashes. The controlled down assist feature does not require operator down pressure, and TRT-1 handles air and electric tools up to 2.7 kg. in weight and 20 Nm torque.

Ergonomic swiveling handpiece allows radial movement but absorbs all torque reaction forces, and rework control allows re-torquing without screw feeding. Radial adjustments allow the tool to be kept vertical, and optional encoders provide positional feedback to identify specific fastener positions. Unique long narrow jaws allow access in areas not possible with other handpieces, and a convenient position trigger on the handpiece provides a remote start for air and electric tools.

- Ergonomic

- Flexible

- Fingertip control

SS SERIES SELF-FEED NUTRUNNER SLIDES

Features

- Mounting for many tool brands

- Dual linear bearings

- models for 0.5 to 30 Nm available

- Lightweight and rigid

- Extended spindle

- Adjustable bit travel

- Optional compression spindle

- Used with pneumatic or electric assembly tools

- Optional upper limit switch

- Slide cover included

- Optional depth sensor