Rotary screw compressor technology has become the standard for high quality, efficient compressed air in the automotive markets. Major advantages of rotary screw compressors include higher capacity, more stable pressure, consistently higher air quality, low vibration, and much quieter operation.

Kaeser knows that today’s automotive facilities have high standards, and with the rising cost of labor, tools, paints, and other materials, re-work is expensive. Dry, clean compressed air at a stable system pressure is essential for high-quality results.

With a Kaeser air system, you get products that have proven reliability and efficiency over and over in demanding industrial applications. Whether your concern is air quality, reducing shop noise, or reducing the time spent on maintenance, Kaeser products can help increase quality, efficiency, and productivity.

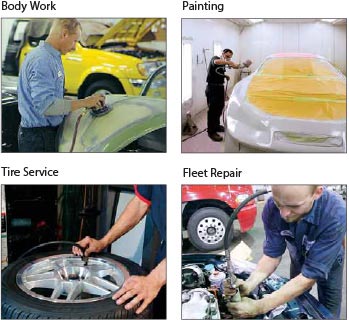

If you need air for fleet service, body, and paintwork, tire service, or general repairs, the most reliable and efficient source of high-quality compressed air is a Kaeser compressed air system.

Is your compressed air system ready for waterborne paint?

If you are a body shop or automotive refinisher you may be facing the challenge of switching to waterborne paints. These coatings have a reputation of being less tolerant of moisture and other contaminants, and many industry professionals say that the change to waterborne basecoats will require new equipment and retrofits. Unfortunately, specific technical specifications about compressed air requirements are hard to come by.

The best collision and automotive finishing shops in America choose Kaeser Compressors for compressed air equipment. Our customers don’t want to compromise finish quality or waste time and materials re-doing paint jobs. They understand the value of a well-designed and reliable compressed air system and know the benefits of clean, dry air.

Shops with good air systems may not notice any difference with waterborne paints but for others, it will be time to make the upgrades they’ve been putting off for years. Also, flash time is longer with waterborne paints, and a popular solution–the blow-drying gun—consumes a lot of compressed air. Many shops may need to add a compressor or move up to a larger one.

Kaeser has many years of experience providing the right compressed air solutions for coating applications. Let us help you determine if you need anything to prepare for a waterborne paint.

One of the industry’s finest paint and body craftsman, Charley Hutton, uses Kaeser air systems to apply waterborne paints. Like many body and paint professionals, Charley was concerned that waterborne paints would impact the quality of his work.

Charley has experienced great success with his Kaeser system: “All my basecoats are waterborne and my Kaeser system works perfectly with them — really clean and dry,” said Charley. “My Kaeser system also works great for my hard clear coats which need super-dry air. For every percent of moisture, you lose 1% of hardness. We can not have that. That is why we rely on Kaeser…they are simply the best!”