Ohio Air Compressor

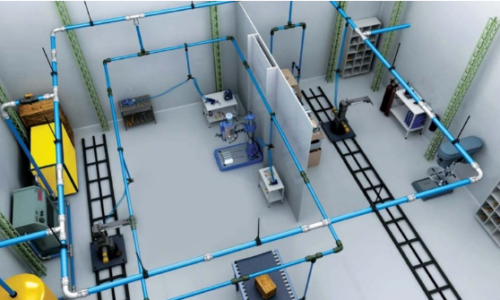

Ohio Air Compressor Distributor Team Air Center is Ohio's air compressor distributor. We have provided Kaeser air compressors and products in Ohio and Michigan since 1984. We offer energy savings analysis to determine how much compressed air you require for your compressed air system and provide additional scalability products for…